KOOM TRANSMISSION TECHNOLOGY offer customers the possibility of supplying complete revolution shafts to place them on the machine ready for assembly.

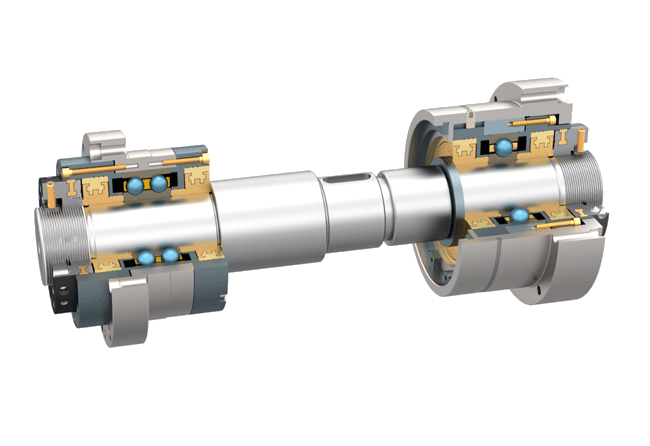

The design of the shaft itself in the areas where the RSK rolling bearings are adjusted must be mechanized following the instructions cited in the corresponding TECHNICAL DATA SHEET.

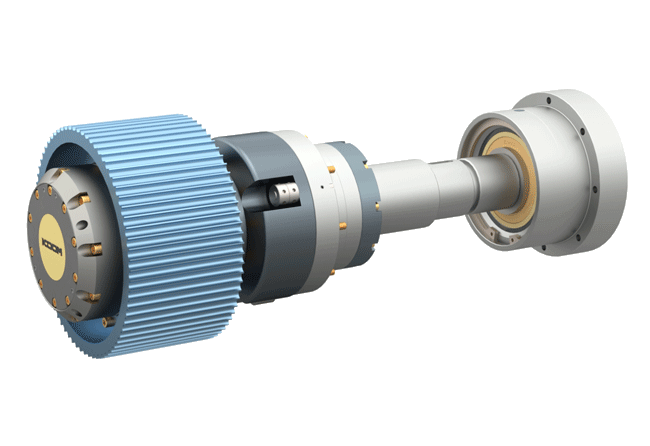

The rest of the design such as lengths, diameters, keyways, and so on, will be designed by the customer, depending on the needs of the machine in question. In the image to the side we see an axle with its respective rolling cartridges and since it is an input axle to the machine, the supply is made with a set of pulley, specifically floating pulleys.